Methods to Power Your Air Compressor with an Industrial Engine

There are many ways to power an air compressor using an industrial engine. Choosing the best way to power your air compressor should be decided by several factors, including space, existing components and systems, weight, and your available engine options. In this article, we provide an overview of the most common methods of powering your air compressor using an industrial engine.

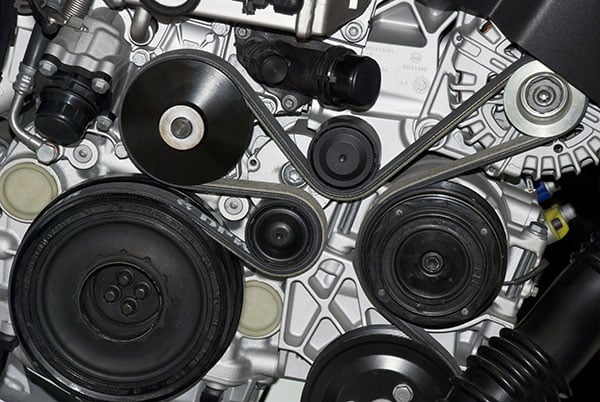

Engine Mounted FEAD Belt Drive

Many systems use an engine-mounted “Front End Accessory Drive” (FEAD) to drive alternators, generators, air conditioning compressors, water pumps, cooling fans, and air compressors. With a FEAD setup, the auxiliary components are mounted directly to the engine and driven from a serpentine or V belt.

Air compressors that use FEAD power can do so in one of two ways:

- in line with the existing belt system, or

- by adding another pulley to the crankshaft and designing another belt system

With the FEAD power method, the driven and driving pulley diameters can be customized to provide the required compressor output at a given engine speed. Belt drives can also provide some damping of potentially damaging torque pulses, which helps with system longevity.

A custom bracket will likely be needed to mount to the engine to support the compressor and if equipped, the secondary belt system components such as the idler(s) and tensioner. The air compressor itself can be driven via a clutch or fixed pulley, depending on whether it’s desirable to completely stop the compressor while the engine is running.

VMAC’s UNDERHOOD air compressors utilize the FEAD power method.

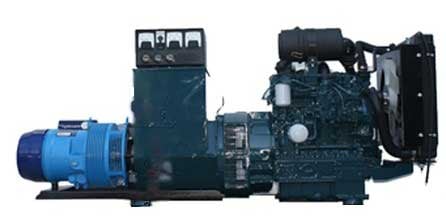

Frame Mounted Belt Drive

The FEAD system has many advantages, but it can be challenging to mount an air compressor to an engine. In this scenario, a frame mounted belt drive can be an ideal alternative.

To simplify the air compressor bracket design, it can be mounted to the base frame instead of the engine. With this design, the belt is still driven off a pulley mounted to the engine’s crankshaft, but the compressor itself is located further away, where more space is available.

Typically, frame mounted belt drive systems use a V belt instead of a serpentine belt. V belts are better at handling misalignment and variations in tension, which can occur between the engine and air compressor under operating conditions—especially if the engine is not hard mounted to the frame.

For example, VMAC has co-designed the frame mounted belt drive system pictured below.

Auxiliary Port Direct Drive

Many industrial diesel engines and some gasoline engines come equipped with an auxiliary PTO port, which is used to power bolt-on accessories. These ports are usually part of the front or rear engine cover and are driven via the crankshaft/camshaft/fuel pump gear-train.

Many industrial diesel engines and some gasoline engines come equipped with an auxiliary PTO port, which is used to power bolt-on accessories. These ports are usually part of the front or rear engine cover and are driven via the crankshaft/camshaft/fuel pump gear-train.

Auxiliary ports come in various configurations usually conforming to an industry standard. The connection to the drivetrain is either a splined port or direct gear mount, depending on the sophistication of the design. Over or under drive ratios may also be available via bolt-on adaptors.

Traditionally, only small reciprocating compressors were driven by auxiliary ports. However, some higher volume rotary screw air compressor designs now take advantage of this PTO drive method too. VMAC’s PTO air compressor is one example of this type of design.

Flywheel Direct Drive

A common way to power an air compressor is to drive it through a coupling directly off the flywheel. This setup often uses industrial couplings designed to dampen vibration and torque spikes, while forgiving some misalignment between the engine and air compressor. A speed increasing gearbox is frequently used to help generate the high RPM required for rotary screw air compressor operation. These compressors can also be coupled with an electric motor or generator.

Flywheel Belt Drive

A pulley and belt configuration can be connected to the flywheel to power your compressor, similar to the FEAD drive system described at the start of this article. However, the flywheel system isn’t as popular because there are more components to work around when using the flywheel. Designing a bracket and belt system for the FEAD is typically more straightforward.

Hydraulic Drive

If the engine or equipment uses hydraulic power for other functions, adding hydraulic power to run a compressor can be a convenient option. While not directly mounted to the engine, the use of an engine-driven hydraulic motor to power an air compressor is common.

Hydraulic power is less efficient when compared to the direct drive methods discussed above, as it may require additional hydraulic cooling capacity and will burn more fuel for a given compressor output. However, this method allows more positional flexibility between the engine and air compressor, which can be helpful if there is limited space on or around the engine.

VMAC’s Hydraulic Driven Air Compressors use this power method.

Electric Drive

Like the hydraulic drive above, using electric power generated by the engine is another way of producing air power. While the availability of sufficient power to produce large air volumes is unlikely, small electric driven compressors can be used when air flow and duty cycle are very low. As electric vehicle technology continues to evolve, it’s likely that more powerful electric driven air compressors will emerge on the market.

Summary

Choosing a drive method for your compressor comes down to your unique situation, air compressor requirements, and equipment available to you. Some methods are more straightforward than others, but each power option has its time and place. The choice of how best to drive your air compressor system is best discussed with the members of the application team of your engine distributor and your air compressor manufacturer.