How Inlet Temperature Affects Your Air Flow

When designing an air compressor or purchasing a pre-designed system for your work, it’s important to consider where your compressor air intake is located because the location directly impacts the compressor’s performance.

There are three critical factors to consider with the inlet location:

- Particulates in the air (dust which can plug filters)

- Ingestion potential; can the intake become plugged with snow or mud?

- Temperature of the air when it enters the compressor

This article will focus on air temperature and its impacts on air flow.

If you are mounting an air compressor to an internal combustion engine or in any type of enclosure, the ambient air temperature around the compressor can rise well above the outside ambient temperature.

When inlet temperature increases, it can cause a significant reduction in compressor performance, reducing the compressor’s ability to output air and perform its job.

Why Does Increased Air Temperature Result In Lower Compressor Output?

Most air compressors are naturally aspirated displacement compressors; the intake air enters the compressor at atmospheric air temperatures and pressures, and the compressor raises the pressure by reducing the air volume by a fixed amount.

If air temperature rises, the air density decreases, and that air takes up more space. The amount of air compressed depends on the density of the air entering the compressor, which correlates to the temperature of the air. Because air compressors can only intake a fixed volume of air, a decreased density due to a higher temperature results in less air within the system that is capable of being compressed.

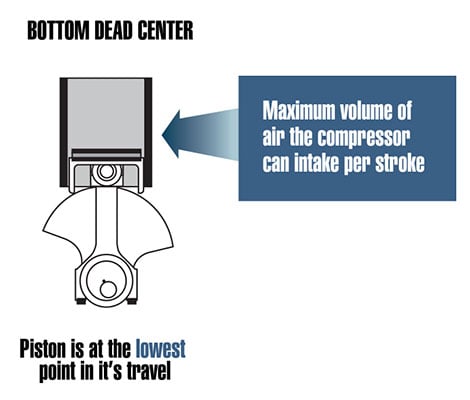

It’s easiest to picture this impact when visualizing a reciprocating air compressor. The maximum amount of air a compressor can intake during each stroke is the volume of the cylinder when the piston is at the bottom of the stroke (bottom dead center), and the cylinder can hold the maximum amount of air.

If the air that the compressor has sucked in during the intake stroke is at a reduced density because of higher temperatures, then the compressor is compressing less air and will require more compression strokes to fill a receiver tank to a pre-determined operating pressure, such as 150 psi.

How Much Difference Does Air Density Make?

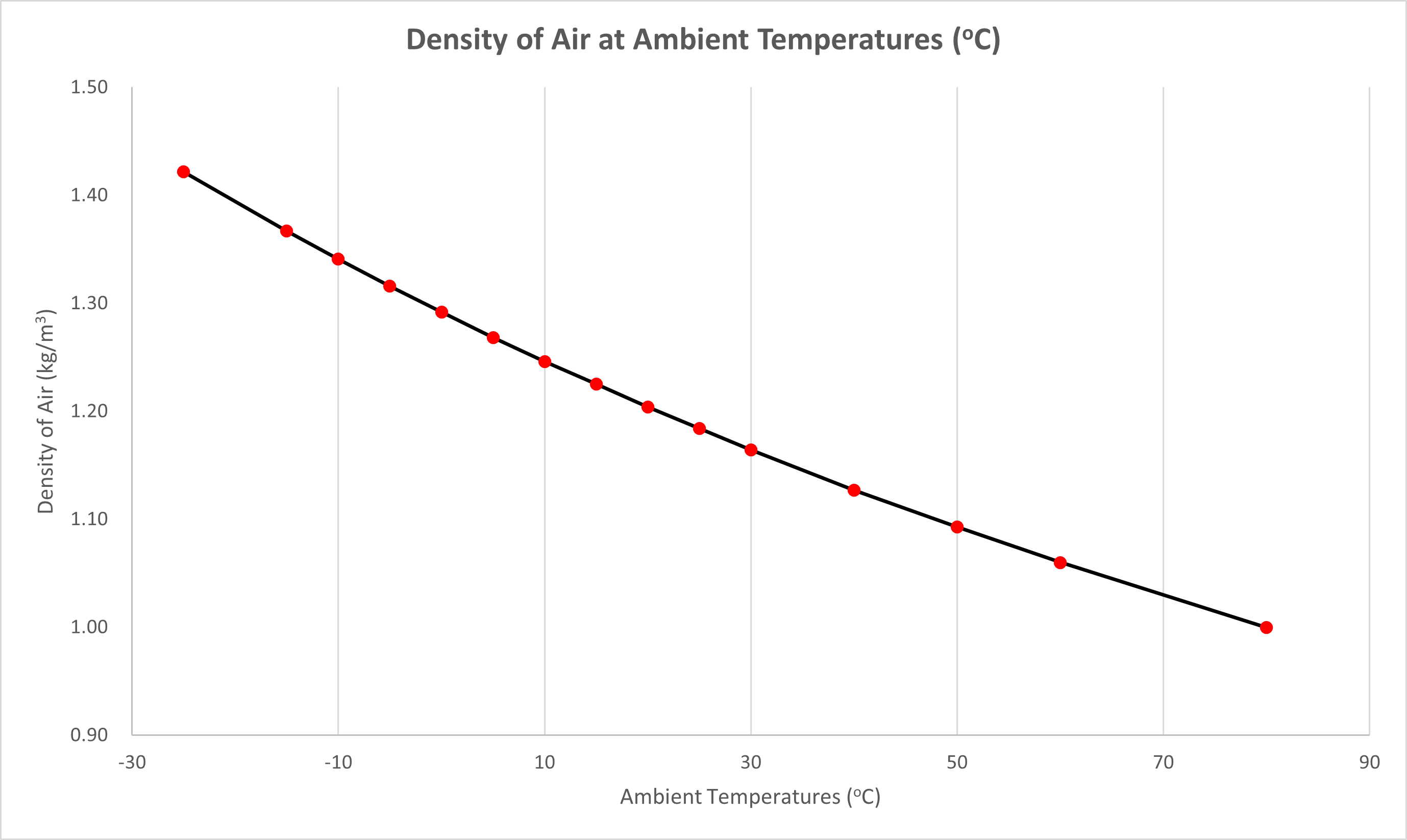

Air density varies with temperature (see graph below), and the air compressor's output is proportional to the density of the incoming air. If the compressor is drawing air out of an engine compartment that is at 80oC (176oF), it will get air at a density of 1.000 (kg/m3) [1].

If instead, you can direct the intake inlet to get “cold” ambient air at 20oC (68oF), the compressor will get the same volume of air at a density of 1.204 (kg/m3). This results in a 20.4% increase in compressor output.

How do I solve air inlet temperature problems?

While many factors affect compressor performance, intake temperature is an important one. One of the quickest and most cost-effective ways to reduce inlet temperature is with a longer intake tube for the air filter. For the relatively low cost of a longer intake tube, a performance increase of 10-20% is plausible.

Combining an intake tube with other performance tips, such as improving hose sizing and performing periodic maintenance on your intake filter, can have powerful results. In some cases, you can use a smaller compressor, resulting in lower upfront costs and operating costs for your compressor system.