Compressed Air Filtering Basics – Contaminants, Filters & More!

Take a deep breath. Breathe out. Breathe in… Now, let’s talk about all the contaminants in that air you’re breathing!

Atmospheric air is naturally contaminated. In addition to oxygen, air also contains water vapor, dust and dirt, and a medley of other filthy particles depending on the surrounding environment. The average metropolitan area, for example, contains approximately 4 million dirt particles per cubic foot of air.

When air is compressed, some of those contaminants need to be filtered out. Contaminated atmospheric air can cause damage to air compressors and air tools, and isn’t acceptable for certain medical and industrial applications.

But atmospheric air isn’t the only source of contamination for compressed air. Air compressors contribute their own share of pollution from wear particles and, if the compressor is oil-lubricated, carbonized compressor lubricant.

Between atmospheric air contamination and air compressor system contamination, there’s a lot of particles dirtying up our compressed air. Fortunately, we have compressed air filtering to save the day.

A Bit of Dirt Never Hurt Anyone…

Don’t worry about that dirty air you’re breathing. Your lungs act as your body’s filtration system, removing contaminants after they’re inhaled. Air compressor systems obviously don’t have lungs, but they do filter out air contaminants in other ways. Better still, a little contamination is usually okay.

Contaminated particles are measured in microns. The bigger the particle, the bigger the micron. Most fine particle tests use 0.3 micron as the standard to measure liquid or solid particle filtration. If a filter tested on this particle size proves to be 100 % efficient, then it’s fairly safe to say this filter can remove any particle above this size.

Many compressed air applications can handle contamination levels well above 0.3 microns. Tire service, construction, and most other mobile air compressor applications tend to tolerate quite a bit of contamination without problem. Operators with these types of jobs can get away with a more basic filtration system, such as an intake filter, which eliminates contaminants in the 30 to 40 micron range.

Industrial air compressor applications tend to be less tolerant of contamination than mobile applications and up to 80 % of industrial contamination is smaller than 2 microns. Therefore, many industrial air compressors need better filtration than mobile air compressors. Industrial air compressor systems often utilize advanced dry particulate and coalescing filters that can clean air down to 0.01 microns. For applications that require super-clean air for OSHA purposes, an additional charcoal activated filter may also be used.

However, these industrial applications are the exception. Outside of massive factories and industrial enterprises, most people use mobile-style air compressors that can tolerate quite a bit of contaminants and don’t need to think twice about their air compressor’s filtration capabilities.

What Contaminants Are In Compressed Air?

Now that you realize just how contaminated our air is, let’s talk about what it’s contaminated with.

Compressed air contains three types of contaminants:

- Dry particulates

- Vapors

- Aerosols

Dry particulates are exactly what they sound like: dirt and other tiny solid particles. Vapors are the gas-forms of particles that condense into liquids at lower temperatures—for example, water. (The gas state is what allows these “liquids” to exist in air.) Meanwhile, aerosols are very fine solid particles that get trapped in air or gas, becoming suspended. Airborne dust is one familiar example of an aerosol.

Each type of contaminant has its own unique characteristics and properties, requiring their own filtration methods.

There are two primary types of filtration that are used in compressed air systems:

- Dry Particulate Filtration

- Vapor & Aerosol Filtration

In the next couple sections of this article, we’ll talk about these filtration types and the filters used to eliminate dry particulates, vapors, and aerosols.

The Principles of Dry Particulate Air Filtration

Here’s where we get technical. We already know that most contamination in a compressed air system can be removed simply by filtration. However, it’s important that your air compressor systems use the correct type of filtration for the particles being filtered.

Dry particulate filters rely on three principles to separate contaminants from the air:

- Direct interception

- Inertial impact

- Diffusion & Brownian movement

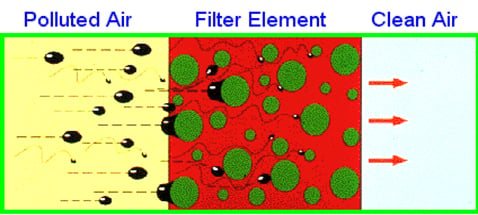

Direct interception affects the larger particles in an air stream, which are literally sieved out through a filter.

Inertial impact occurs when a particle traveling in an air stream is eventually unable to negotiate the torturous path between the filter fibers and cannot change direction as quickly as the air stream. The contaminants then collide with a fiber and become attached to it.

Diffusion or Brownian movement affects fine particles. With diffusion, small particles merge with other gas particles and begin to move erratically. This erratic movement is called Brownian movement. As these particles move separately from the compressed air flow, they are more likely to become trapped in the filter.

All three of these principles work together in a dry particulate filter to capture and trap contaminants from the compressed air.

If you’re interested in reading more about the principles and physics behind air filtration, check out this “Mechanism of Filtration For High Efficiency Fibrous Filters” report by TSI.

Vapor & Aerosol Filtration for Compressed Air

Vapors and aerosols slip past dry particulate filters, which may require their own filtration systems. In this case, there are two options that may be utilized:

- Coalescing

- Adsorption

Coalescing filters trap moisture and oil. The compressed air enters through the inlet port and travels down into the filter, passing through a filter media before it leaves through the discharge port. Moisture and oil droplets bond together during this process, forming larger droplets that then drip into a moisture trap below.

Coalescing filters are commonly used in oil-injected air compressors, such as rotary screw air compressors. In VMAC systems, these filtration methods include a couple types of dry particulate filters, as well as a coalescing filter.

Adsorption filters help eliminate vapors and lubricants, using activated charcoal or similar chemicals to bond with the vapor molecules. Adsorption comes into play when vapors must also be eliminated from a system. Adsorption filters are typically only used in specific industrial applications.

Filtration Systems of Rotary Screw Air Compressors

Reciprocating air compressors that don’t use oil can often get away with just a dry particulate filter. That’s because the contaminants in atmospheric air are negligible for most construction and automotive applications, travelling through the air compressor without causing much problem.

However, oil-injected rotary screw air compressors require additional levels of filtration. The oil used to lubricate the rotors is necessary for this style of air compressor, but that same oil needs to be cleaned and separated from the air.

Therefore, rotary screw air compressors require two types of filtration systems:

- Dry particulate filters

- Coalescing filters

In a typical VMAC air compressor, you’ll find both types of filters throughout the system:

- Air filter: atmospheric air entering the system goes through a dry particulate air filter.

- Coalescing filter: Air that leaves the rotors, now mixed with oil, goes through a coalescing filter, which separates the oil from the clean air. The oil gets recirculated while the air exits the system.

- Oil filter: The separated oil then goes through the oil filter, which is another dry particulate filter that separates particles from the oil.

It’s these same filters that occasionally need to be replaced and will be included with VMAC’s service kits. Replacing the air filter, oil filter and coalescing filter ensures the air compressors continue to trap contaminants and keeps your air compressor in tip-top shape.