Air Compressors For Construction Work

Construction workers build the world around us, so it’s critical they have reliable tools and equipment that get the job done right. Air compressors for construction work are no exception; the right compressor makes your work safer, faster and easier.

Air Compressor Requirements For Construction

When choosing an air compressor for construction work, it’s crucial to consider many factors, including:

- CFM

- PSI

- Application/tool use

- Job site location

Most tools and equipment used on the job site will be relatively low CFM, requiring less than 40 CFM, but there are some common exceptions. 1” impact wrenches and 60 lb pavement breakers typically require 60-70 CFM, while larger tools such as rock drills and #5 spline impact wrenches need 100 CFM plus.

Most tools and equipment used on the job site will be relatively low CFM, requiring less than 40 CFM, but there are some common exceptions. 1” impact wrenches and 60 lb pavement breakers typically require 60-70 CFM, while larger tools such as rock drills and #5 spline impact wrenches need 100 CFM plus.

It’s important to look at the tools you’ll use on your job site to determine your CFM requirements. Consider your most common applications and what CFM they will likely require. If you aren’t sure, higher CFM is the safer bet.

PSI is another minor consideration when choosing air compressors for construction. Fortunately, most tools and air compressors are aligned at around 150 PSI. Stick to the standard unless you have a specialized application that specifically requires more or less PSI.

Finally, where you work greatly impacts the air compressor you should use. Construction work is everywhere, and job sites frequently change, making mobile air compressors the best option for this type of work. Avoid skid-mounted and stationary air compressors because there are better solutions out there, as you’ll see later in this article.

Types Of Mobile Air Compressors For Construction Work

Mobile air compressors make construction work easier, helping ensure your compressed air is always where it needs to be. There are three common types of mobile air compressors used in construction work:

- Tow-behind

- Above Deck

- Vehicle Integrated / Underdeck

Each air compressor has its pros and cons, and the last two options are better for mobile work. Let’s discuss why.

Tow-Behind Air Compressors

Tow-behind air compressors are commonly used at construction job sites because they are familiar and easy to source. Many rental shops and construction companies already have these compressors on hand.

But a tow-behind air compressor is a decent solution in only one of two circumstances: you only need air for a single job, or you require extremely high CFM for specialized applications.

Most of the time, there are too many disadvantages to a tow-behind air compressor to consider it an ideal mobile air option. The disadvantages of tow-behind air compressors include:

- Must be towed to and from every job site

- Often needs a vehicle to reposition within the job site

- Logistical challenges accessing job sites

- Takes up hitch space

- Requires additional safety checks & measures

- Additional fuel costs

- Additional engine maintenance

- Additional insurance requirements

For a more detailed breakdown of these disadvantages, check out these 9 Reasons To Ditch Your Tow-Behind Air Compressor. Otherwise, let’s jump to superior mobile air solutions.

Abovedeck Air Compressors

Some of the best mobile air compressors on the market today are abovedeck air compressors. These compressors are built for service vehicles and mounted to the vehicle’s deck. They are intentionally designed to withstand the same rugged work conditions the vehicle is intended for and can handle the abuse of day-to-day construction work.

When choosing an abovedeck air compressor, there are typically two options: rotary screw or reciprocating. Rotary screw air compressors are almost always the way to go because they are better quality, have significantly higher longevity, and operate at 100% duty cycle.

When choosing an abovedeck air compressor, there are typically two options: rotary screw or reciprocating. Rotary screw air compressors are almost always the way to go because they are better quality, have significantly higher longevity, and operate at 100% duty cycle.

The only reason to ever choose reciprocating over rotary screw is if you have lower air demand and budget limitations, as reciprocating air compressors are typically less expensive due to their low performance and short life span. However, you get what you pay for in this circumstance, and rotary screw air compressors are without a doubt the ideal abovedeck compressor style.

The other primary consideration for abovedeck air compressors is the fuel type. As a general rule, you’re going to make your life a lot simpler if you match your air compressor fuel to your vehicle’s fuel type. For this reason, choose a gas-powered air compressor for a gas vehicle, and a diesel-powered air compressor for a diesel vehicle.

The other primary consideration for abovedeck air compressors is the fuel type. As a general rule, you’re going to make your life a lot simpler if you match your air compressor fuel to your vehicle’s fuel type. For this reason, choose a gas-powered air compressor for a gas vehicle, and a diesel-powered air compressor for a diesel vehicle.

If your truck has a crane, you can also look at hydraulic air compressors connecting to the vehicle’s existing hydraulics system. Hydraulic air compressors are an excellent option due to their performance and durability.

Vehicle Integrated Air Compressors

Vehicle-integrated air compressors are by far the most innovative air compressor solution for construction work. The two types of vehicle-integrated air compressors available on the market today are UNDERHOOD and underdeck air compressors.

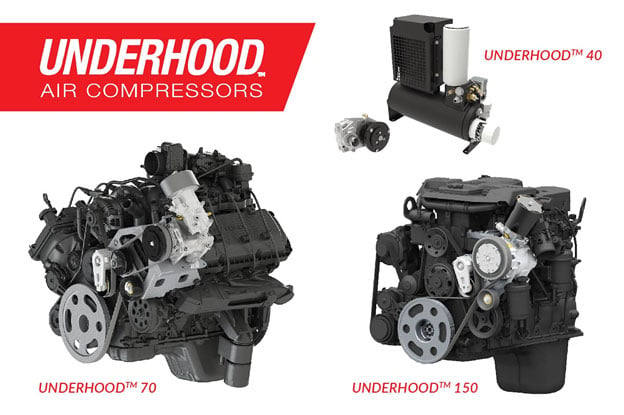

UNDERHOOD Air Compressors

UNDERHOOD air compressors are a belt-driven solution mounted within the engine compartment of a vehicle. VMAC works specifically with OEMs like Ford, RAM, and Chevy to ensure these air compressors are compatible with the latest model year vehicles they are designed for while maintaining all existing warranties.

UNDERHOOD air compressors are an ideal solution for construction work because they are compact and lightweight. Their positioning within the engine compartment means UNDERHOODs are always available anywhere your truck goes without taking up deck or hitch space.

The UNDERHOOD comes in four models:

- UNDERHOOD 40 Truck Series – Produces up to 40 CFM

- UNDERHOOD 40 Van Series – Produces up to 40 CFM

- UNDERHOOD 70 – Produces up to 70 CFM

- UNDERHOOD 150 – Produces up to 110 CFM

The UNDERHOOD is a great solution for construction workers who want to save cargo space and reduce GVW without compromising on productivity or convenience.

Learn more about UNDERHOOD air compressors here!

Underdeck Air Compressors

Underdeck air compressors provide many of the same benefits as UNDERHOOD air compressors, with some notable differences. Underdeck air compressors are mounted underneath the deck of a vehicle, allowing similar benefits as UNDERHOOD but with a different configuration and installation process.

For example, some underdeck systems are bulky, heavy, and require the purchase and installation of an additional drive shaft, as well as modifications to the vehicle transfer case. But there are many different styles of underdeck air compressors, and some are better than others.

One of the best options on the market today is VMAC’s direct-transmission mounted air compressors, which connects to a PTO port on to the vehicle’s transmission. This innovative design avoids many of the disadvantages of other underdeck systems, as the system is small and lightweight and doesn’t require an additional shaft or transfer case modifications.

When looking at underdeck solutions, consider options that are lower in weight, have the fewest moving parts, and meet your CFM and vehicle requirements.

Check out our article, “What’s The Deal With Underdeck Air Compressors?” to learn more about these unique systems.