Rotary Screw Air Compressor Oil – Answers To Your Top 8 FAQs!

What is air compressor oil?

Air compressor oil is standard or synthetic oil made specifically for air compressors. Unlike motor oil, air compressor oil does not contain detergent and typically has lower amounts of carbon, sulfur, and other contaminants that can cause build-up.

Air compressor oil is standard or synthetic oil made specifically for air compressors. Unlike motor oil, air compressor oil does not contain detergent and typically has lower amounts of carbon, sulfur, and other contaminants that can cause build-up.

Generally, rotary screw air compressors use synthetic oil, while recreational compressors may use standard oil. Air compressor oil varies in composition and color but is often yellow or light brown and becomes darker as it becomes contaminated over time.

Why do rotary screw air compressors need oil?

Air compressor oil plays several vital roles within a rotary screw air compressor system:

- Lubricates moving parts

- Creates a seal between rotors to trap air

- Prevents premature wear on parts

- Helps cool air during compression

Rotary screw air compressors are sometimes “oil flooded” or “oil injected,” describing that oil is injected into the rotor housing. The oil mixes with the air during compression but is separated back out before the compressed air leaves the system.

Some rotary screw air compressors don’t require oil at all. However, these designs tend to be louder and more expensive. Oil-free rotary screw air compressors are typically only used in industrial applications in which oil contamination absolutely can’t occur, such as food processing or medical oxygen.

What kind of oil does an air compressor take?

Some air compressors require a particular type of oil, while others may not be as specific. Before deciding on a type of oil for your rotary screw air compressor, check your manual and warranty details to determine whether a particular oil is required.

If a manufacturer specifies a type of oil, always use that oil. For example, all VMAC air compressors require VMAC’s high-performance synthetic rotary screw compressor oil to perform correctly and maintain the limited lifetime warranty. We have tested all our systems with this oil and know it has the perfect chemical composition to lubricate and protect components, create proper seals between our two rotors, prevent overheating, and ensure optimal air output.

Manufacturers who don’t specify an exact oil brand may still recommend a 20-weight or 30-weight non-detergent oil. 20-weight oil is typically used in colder environments, while 30-weight oil is better suited for warm climates. Some operators will switch between these oils for the summer and winter seasons.

When should I change air compressor oil?

Maintaining proper service intervals will keep your air compressor running in optimal condition and help maintain the warranty. You should always check and follow your air compressor manufacturer’s service maintenance schedule.

For example, here is a breakdown of VMAC’s air compressor oil service intervals:

| System | Compressor Type | Oil Service Intervals |

|---|---|---|

| G30 | Gas Powered | 200 Hours / 6 Months |

| D60 | Diesel Powered | 500 Hours / 6 Months |

| H60 | Hydraulic Driven | 500 Hours / 1 Year |

| DTM70 | PTO Driven | 200 Hours / 6 Months |

| UNDERHOOD® 70 | Engine Mounted | 200 Hours / 6 Months |

As you can see, the service hours and periods range significantly between different air compressors—even when designed by the same manufacturer. Therefore, you should always check your air compressor’s manual when determining when to change the compressor oil for your system. Contact the manufacturer directly if you can’t locate a manual for your system.

How do I check the air compressor oil level?

Check your air compressor oil level daily, or every time you use the air compressor. To check the oil level, follow these simple steps:

- Ensure the vehicle is parked on level ground and that the compressor system is depressurized and cool to the touch.

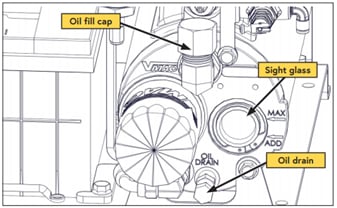

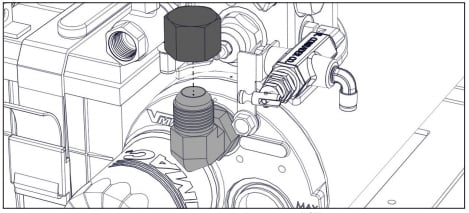

- Check the oil level in the sight glass. On VMAC systems, ensure the oil is between the “MAX” arrow and the “ADD arrow.”

- If the level is below the required level, remove the fill cap on the tank and use a funnel to pour oil into the fill fitting. Use the sight glass to achieve the desired oil level and avoid overfilling.

- Replace the fill cap and tighten it securely.

If the air compressor does not have a sight glass, remove the oil fill cap and look inside for a dipstick. Pull out the dipstick and look for the “min” and “max” lines at the bottom tip of the stick, then use these lines to determine whether more oil is needed.

How to change air compressor oil?

When changing your air compressor’s oil, follow the instructions in your manual. Although the basics of an oil change are simple—drain the old oil and then pour in new oil—the individual steps can be significantly more detailed.

As an example, here are the steps required to change the oil in VMAC’s G30 gas powered air compressors:

- Clean the area around the air compressor’s WHASP tank and oil filter to prevent contamination.

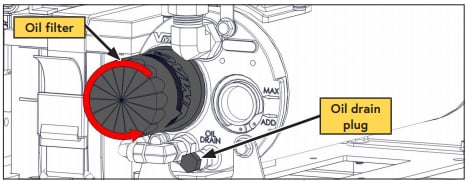

- Remove the oil drain plug and drain the oil into a container with a capacity of at least 1 gallon (4L).

- Inspect the Viton O-ring on the oil drain plug for damage, hardness or defects and replace if necessary.

- Install and tighten the oil drain plug.

- Remove the oil filter.

- Ensure the threaded nipple did not unscrew with the oil filter.

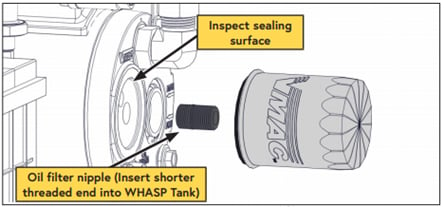

- If the nipple came out with the oil filter, remove it from the filter, being careful to avoid damaging the threads.

- To reinstall the nipple, thoroughly clean the threads, apply Loctite 242 (blue) to the end with the short threads, and replace it in the air oil separator tank.

- Clean the gasket sealing surface on the front of the tank and inspect it for damage. The surface must be smooth and free of old gasket material to ensure a good seal.

- Apply a thin coat of compressor oil to the rubber gasket on the oil filter.

- Spin the filter onto the threaded nipple until the gasket contacts the sealing surface on the tank, then tighten the filter an additional 3/4 to 1 turn to seat the gasket.

- Remove the filler cap on the WHASP Tank. Fill the WHASP Tank with VMAC compressor oil until the oil in the sight glass reaches the “MAX” mark. The air compressor system holds approximately 1 gallon (4L) of oil.

- Check the oil level at the sight glass on the front of the WHASP Tank. Continue adding oil until the level is correct.

- Reinstall the fill cap.

- Start the engine and check for oil leaks.

- Allow the system to build to pressure (factory setting 145 psi) and for the engine speed to decrease to base idle.

- Turn off the engine.

- Once the system has sat for 5 minutes, check the oil level through the sight glass. The level must be between the “MIN” and “MAX” level indicators.

- Verify there are no oil leaks.

How much air compressor oil do I need?

There is a significant range in how much oil air compressors require, with no clear standard across manufacturers. VMAC air compressors hold approximately 1-2 gallons (4-9 liters) of compressor oil, depending on the VMAC system, but other systems may contain more or less oil. Read your air compressor’s manual or contact the manufacturer directly to determine how much oil your air compressor system will require.

Where can I buy air compressor oil?

You can buy air compressor oil from air compressor dealers, hardware stores, and some auto shops. VMAC air compressor oil can be purchased through any authorized VMAC dealer.