5 Reasons You Shouldn’t Use A PTO Shaft Driven Air Compressor

All things aren’t equal with vehicle-integrated air compressors, and some solutions are better than others, which is especially true with PTO-driven air compressors. This article shares five reasons you shouldn’t choose a shaft-driven PTO air compressor.

5. There Are Better PTO Driven Air Compressors Available

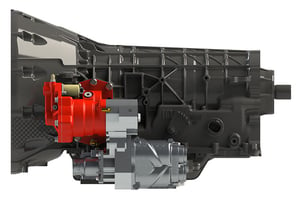

Air compressor technology is constantly changing. What was once a standard underdeck system is now running its course and being replaced by a significantly more updated style of PTO air compressor—direct transmission mounted (DTM). DTM air compressors are mounted directly to the PTO and, because they are engineered fit neatly among a vehicle’s existing components, you eliminate all the common issues of a PTO shaft driven system, as noted below.

4. Auxiliary Shafts Can Cause Alignment Issues

Air compressor solutions that use shafts can cause balance issues. When shafts aren’t properly balanced, numerous additional issues can follow. For example, the auxiliary shaft can bend or break. Bearings and u joints can eventually fail throughout the line and within the compressor. In addition, problems with the driveline system because of improper installation often aren’t covered under warranty.

3. PTO Shaft Systems Require More Moving Parts (Which Can Break)

Shaft driven air compressors require an auxiliary drive shaft to connect the air compressor to a side-mount PTO. Having an additional moving part is a liability because it can break and damage other components below the frame rail.

2. Shaft-Driven Air Compressors Are Expensive To Install

Along with the additional cost of the auxiliary drive shaft, PTO shaft driven air compressors require more time to install, which results in significantly higher labor costs. This effort can result in over 10 hours of extra work, typically adding hundreds if not thousands of dollars to installation costs.

1. You’ll Have To Modify The Transfer Case

PTO shaft driven air compressors on Ford SuperDuty or RAM commercial 4X4 trucks require transfer case modifications to install. These aftermarket parts are expensive, time-consuming to install, and require the removed transfer case to be returned to the vendor for credit.

A Superior Alternative To Shaft Driven PTO Air Compressors

Auxiliary shafts add unnecessary costs and risks to PTO air compressors—but you can eliminate these risks with a Direct-Transmission Mounted (DTM) system. The DTM is a PTO air compressor that’s mounted directly to the transmission, and therefore doesn’t require an auxiliary shaft. This is only made possible through VMAC’s innovative UNDERHOODTM products, which are significantly lighter weight, more compact, yet more powerful than typical underdeck air compressors.

Auxiliary shafts add unnecessary costs and risks to PTO air compressors—but you can eliminate these risks with a Direct-Transmission Mounted (DTM) system. The DTM is a PTO air compressor that’s mounted directly to the transmission, and therefore doesn’t require an auxiliary shaft. This is only made possible through VMAC’s innovative UNDERHOODTM products, which are significantly lighter weight, more compact, yet more powerful than typical underdeck air compressors.

Replacing a shaft driven PTO air compressor system with a DTM has numerous benefits, including:

- half the time to install

- less expensive to install

- no transfer case modifications

- no risk of alignment issues

- eliminates unnecessary moving parts

With so many benefits, it’s clear that the Direct-Transmission Mounted air compressor is a sound business choice as a PTO alternative to shaft driven air compressors. The DTM is a superior solution for serious work. Why settle for anything less?

Learn more about VMAC’s DTM70 air compressor here.