Quick Links

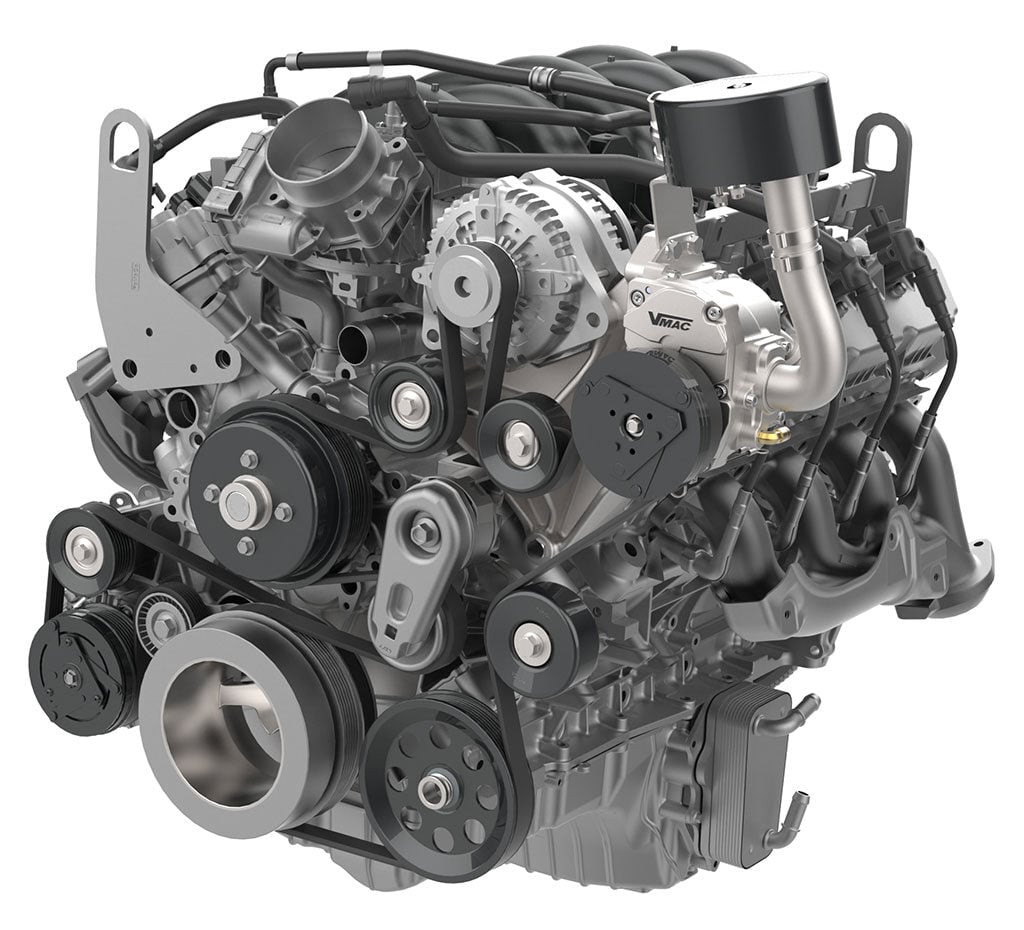

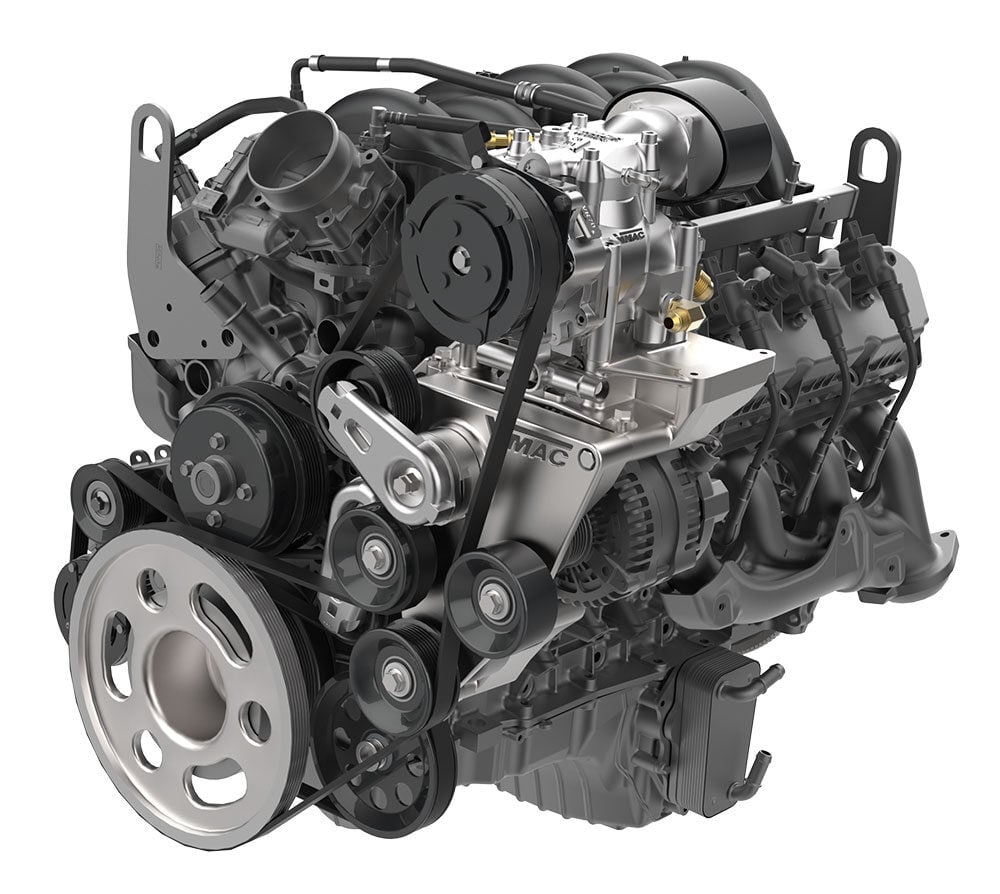

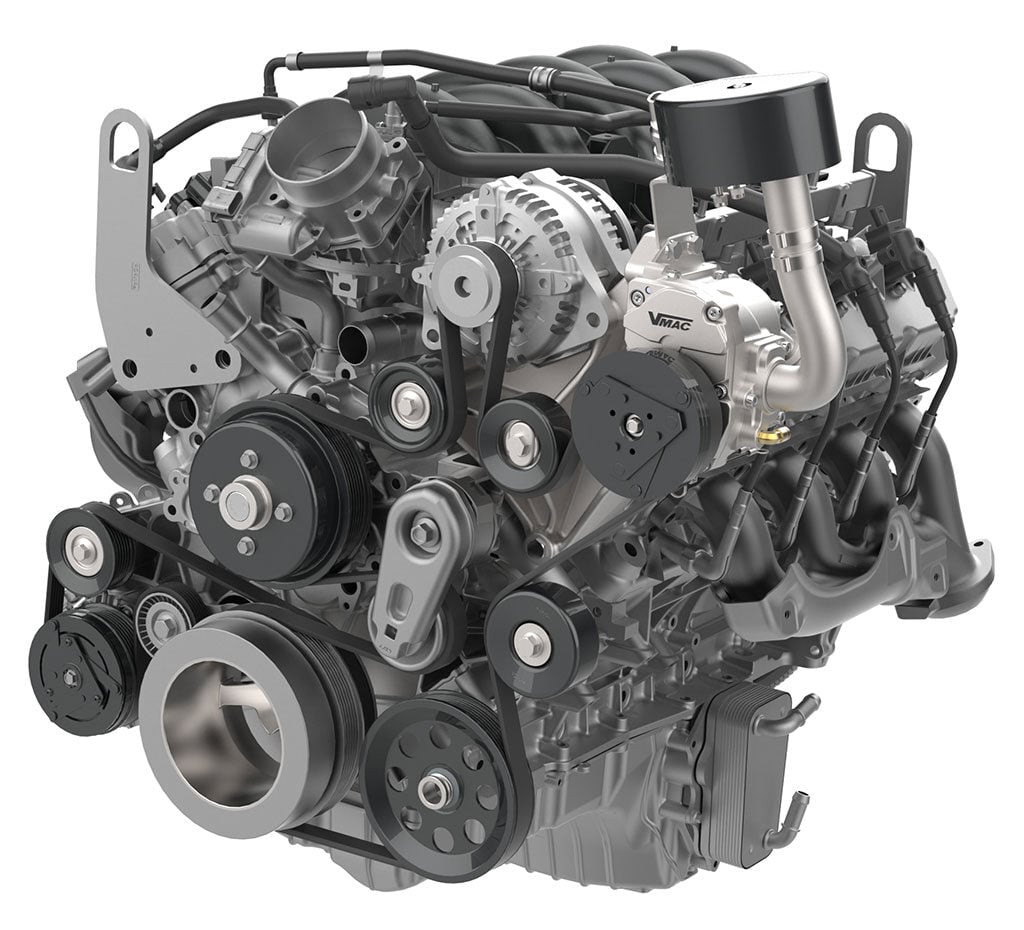

UNDERHOOD® Air Compressors

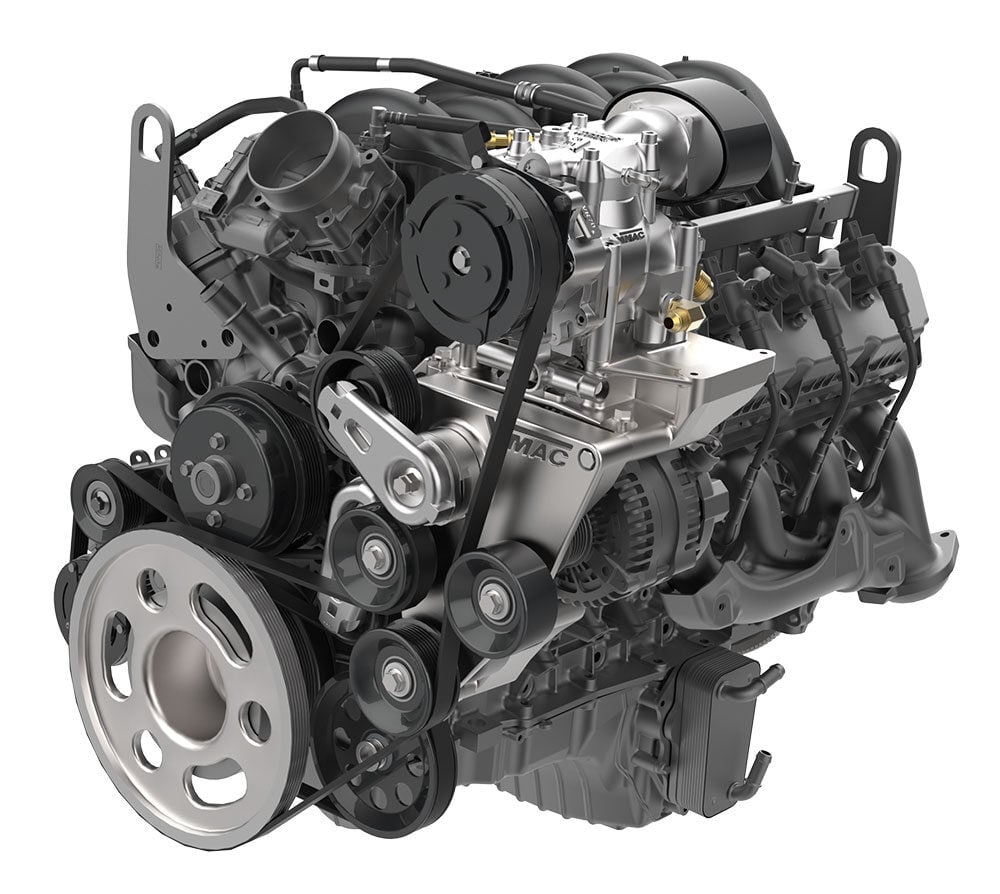

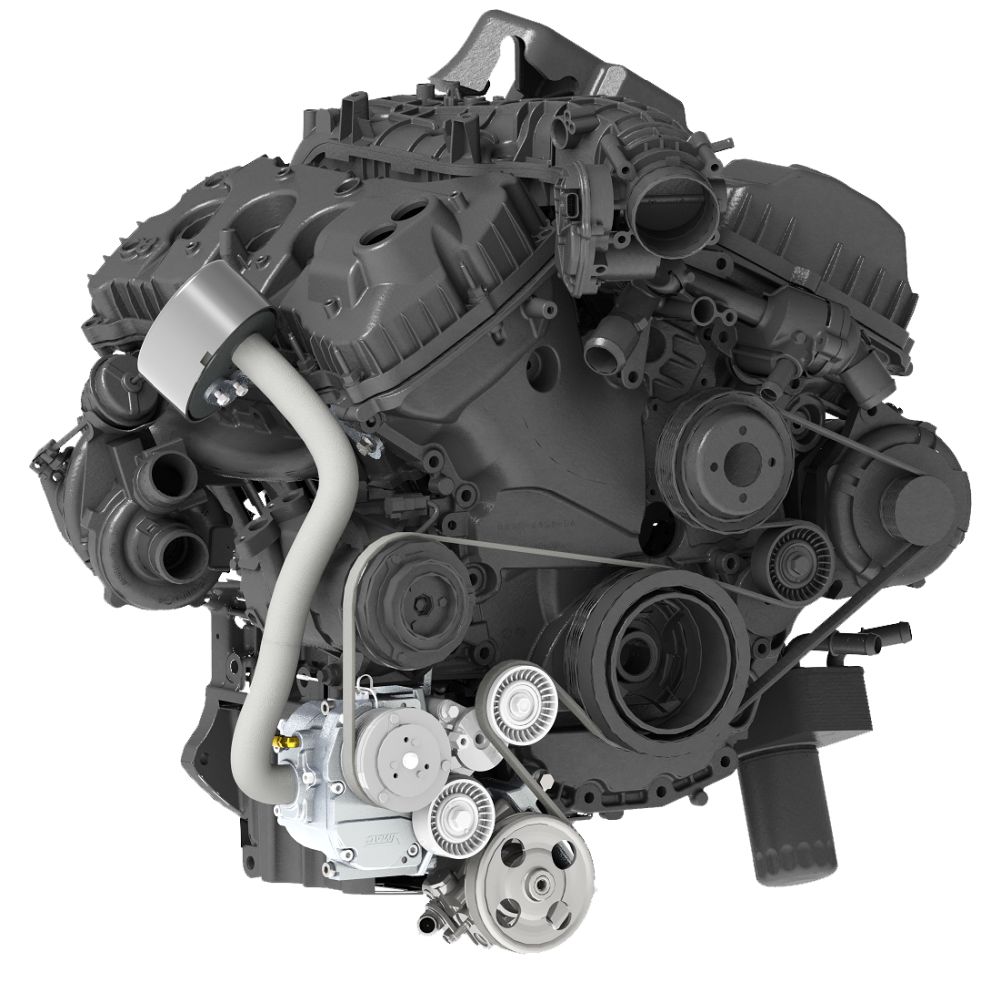

The UNDERHOOD® air compressor is the best choice for customers who need to save cargo space, reduce truck GVW, and minimize maintenance requirements.

All systems feature the patented VMAC rotary screw air compressor that includes a VMAC Lifetime Warranty (Limited).

UNDERHOOD40 Air Compressors – Truck Series

For Ford, RAM, and GMC/Chevrolet service trucks; ideal for operating small air tools like 3/4“ impact wrenches, light chipping hammers and die grinders.

UNDERHOOD40 Air Compressors – Van Series

For Ford, GMC/Chevrolet, and Sprinter commercial vans; ideal for operating small air tools like 3/4“ impact wrenches, light chipping hammers and die grinders.

UNDERHOOD70 Air Compressors

For Ford, RAM, and GMC/Chevrolet service trucks; ideal for operating small to medium sized air tools like 1” impact wrenches, 60 lb jackhammers, backfill tampers, vertical/horizontal grinders and sanders.

UNDERHOOD150 Air Compressors

For Ford and RAM service or utility trucks that currently pull tow-behind portable air compressors or have utility mount air compressors; ideal for operating medium to large sized air tools like 90 lb jackhammers, post-pounders and trenchless piercing tools.

Less Space

UNDERHOOD air compressors free up to 80 cubic feet on the truck deck or cargo area because the air compressor mounts in the engine compartment.

Less Weight

UNDERHOOD air compressors reduce truck GVW by as much as 1,900 lb. Choosing a lightweight air compressor means you’ll be able to add more tools and equipment to your truck, carry more materials, take advantage of better fuel economy, or even downsize your truck classification.

Less Maintenance

UNDERHOOD air compressors require less maintenance because stand-alone engine driven air compressors have their own engines that require servicing and repairs.

More Productivity

UNDERHOOD air compressors use patented rotary screw technology designed to run at 100% duty cycle without stopping or overheating, so operators don’t have to wait for their air compressor.

Any Environment

UNDERHOOD air compressors are proven to work in any extreme climate, chosen as the air compressor system of choice in arctic and desert environments.

UNDERHOOD® Air Compressors - How It Works

Discover the power, performance, and space spacings of our UNDERHOOD air compressor systems in this detailed "How It Works" video. Four UNDERHOOD air compressor models are designed to seamlessly integrate with your vehicle, providing a reliable, high-performance solution for all your mobile air needs. Learn how our innovative systems utilize your vehicle's engine power to deliver consistent air supply on the go.

UNDERHOOD® Air Compressor Operations

Want to learn the most efficient, fast way to operate your UNDERHOOD® air compressor system? Watch this video to learn how to safely and efficiently operate your VMAC air compressor to save time, money and emissions.

UNDERHOOD® Air Compressors For Trucks & Vans: Models From 40 CFM Up To 110 CFM

In this video, Darren Darnley from VMAC gives an overview of VMAC’s line of UNDERHOOD air compressor systems. UNDERHOOD air compressors are installed in the engine compartment of the truck or van, making them the best choice for fleet managers and operators concerned with space and weight on their service vehicles.